Alfalfa is widely recognized as one of the most valuable forage crops in the global feed industry. Rich in protein, fiber, vitamins, and minerals, alfalfa is commonly used for cattle, sheep, horses, and other livestock. However, loose alfalfa hay presents challenges in storage, transportation, and consistent feeding. This is why demand for an alfalfa pellet machine for sale continues to grow among feed producers and agricultural investors.

Why Alfalfa Pelletizing Is a Strategic Choice

Traditional alfalfa hay is bulky and sensitive to moisture. During handling and transportation, nutrient loss and dust generation are common issues. Pelletizing helps address these problems by compressing alfalfa into dense, uniform pellets with controlled moisture and size.

Alfalfa pellets offer several advantages:

- Higher bulk density for lower transport costs

- More consistent nutrient distribution

- Reduced feed waste and dust

- Improved feed intake efficiency

These benefits make alfalfa pellets increasingly popular in both domestic feed markets and export-oriented feed operations.

(Related Post: https://biomasspelletizer.com/alfalfa-pellet-machine-for-sale/)

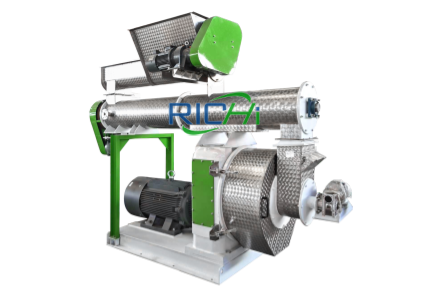

How an Alfalfa Pellet Machine Works

An alfalfa pellet machine is designed to process fibrous forage materials while preserving nutritional value. Before pelletizing, alfalfa is typically chopped and dried to an optimal moisture level. The material is then compressed through a die using rollers, forming cylindrical pellets through pressure and heat.

Compared with biomass-focused equipment, alfalfa pellet machines prioritize:

- Gentle processing to protect nutrients

- Stable pellet shape and hardness

- Smooth discharge and cooling

In many feed mills, the pelleting machine is the core unit that determines final pellet quality and production efficiency.

Industrial Alfalfa Pellet Production Line Solution

For medium and large feed operations, a single pellet machine is rarely sufficient. Instead, producers often adopt a complete industrial alfalfa pellet production line solution to ensure stable output and consistent quality.

Typical Line Configuration

An integrated alfalfa pellet production line usually includes:

- Alfalfa crushing and conveying system

- Drying and moisture control equipment

- Pelletizing section

- Cooling and screening units

- Automatic weighing and packaging system

This systematic layout allows continuous operation while reducing labor intensity and production interruptions.

Flexibility for Different Alfalfa Processing Needs

Alfalfa pellet production varies by region and application. Some producers focus on livestock feed, while others target export-grade pellets with strict quality requirements. A well-designed production line can adapt to these differences.

For example:

- Dairy feed pellets may require higher density

- Horse feed pellets often prioritize smooth surface and uniform size

- Export pellets need consistent moisture and packaging standards

Such flexibility allows producers to adjust formulations and output based on market demand.

Key Factors When Choosing Equipment

When evaluating an alfalfa pellet machine for sale, buyers typically focus on output capacity, energy efficiency, and maintenance requirements. Alfalfa fibers can cause wear if machines are not properly engineered, making durability a critical factor.

Before finalizing equipment selection, reviewing real production cases is highly recommended. You can click to read more about how alfalfa pellet lines are configured in different regions and what performance indicators to consider during project planning.

Applications of Alfalfa Pellets in the Feed Industry

Alfalfa pellets are primarily used as high-quality roughage feed. They are suitable for:

- Dairy cattle and beef cattle

- Sheep and goats

- Horses and camels

Pelletized alfalfa ensures uniform feeding and simplifies ration formulation. In addition, pellets are easier to store long-term without significant nutrient loss, making them ideal for large-scale feed distribution.

In some markets, alfalfa pellets are also blended with grains or supplements to create customized compound feeds.

Importance of Equipment Matching and Line Design

Successful alfalfa pellet production depends not only on the pellet mill itself but also on proper matching of upstream and downstream equipment. Crushing size, drying temperature, and cooling efficiency all affect final pellet quality.

A properly matched pelleting machine within a well-designed production line helps reduce breakdowns, improve pellet appearance, and lower operating costs over time.

Market Outlook for Alfalfa Pellet Production

As livestock farming becomes more intensive and feed efficiency gains importance, alfalfa pellet demand is expected to remain strong. Regions with limited pasture availability increasingly rely on pelletized forage as a stable feed source.

By investing in a reliable alfalfa pellet machine for sale and a suitable industrial alfalfa pellet production line solution, feed producers can improve production control, reduce logistics costs, and respond more effectively to market changes.

Conclusion: Building a Competitive Alfalfa Pellet Operation

Alfalfa pelletizing represents a mature and sustainable feed processing solution. With proper equipment selection and system design, loose forage can be transformed into standardized, high-value feed products.

For investors and feed manufacturers, choosing the right pelleting technology is a key step toward long-term operational success and market competitiveness.