With the global livestock and aquaculture industries moving towards intensification and standardization the demand for high-quality and efficient feed production equipment is soaring. An animal feed pellet plant is the core backbone of modern feed manufacturing enabling large-scale standardized and high-quality feed production. From poultry and swine to ruminants and aquatic animals different livestock species have unique feed requirements which drive the diversification of feed pellet mills and production lines. Choosing the right production line and supporting equipment is crucial for reducing costs improving feed quality and enhancing breeding benefits.

Key Components of a Complete Animal Feed Pellet Plant

A standard animal feed pellet plant consists of multiple coordinated equipment modules each playing a vital role in ensuring the smooth operation of the entire production process. The core components include:

- Raw Material Crushing Equipment: Responsible for crushing bulk raw materials such as corn soybean meal and straw into fine particles that meet pelleting requirements. The crushing fineness directly affects the digestibility of feed and the efficiency of subsequent pelleting.

- Mixing Equipment: Uniformly mixes various raw materials and additives according to the feed formula to ensure that each animal gets balanced nutrition. High-precision mixing equipment can avoid nutrient segregation and improve feed quality stability.

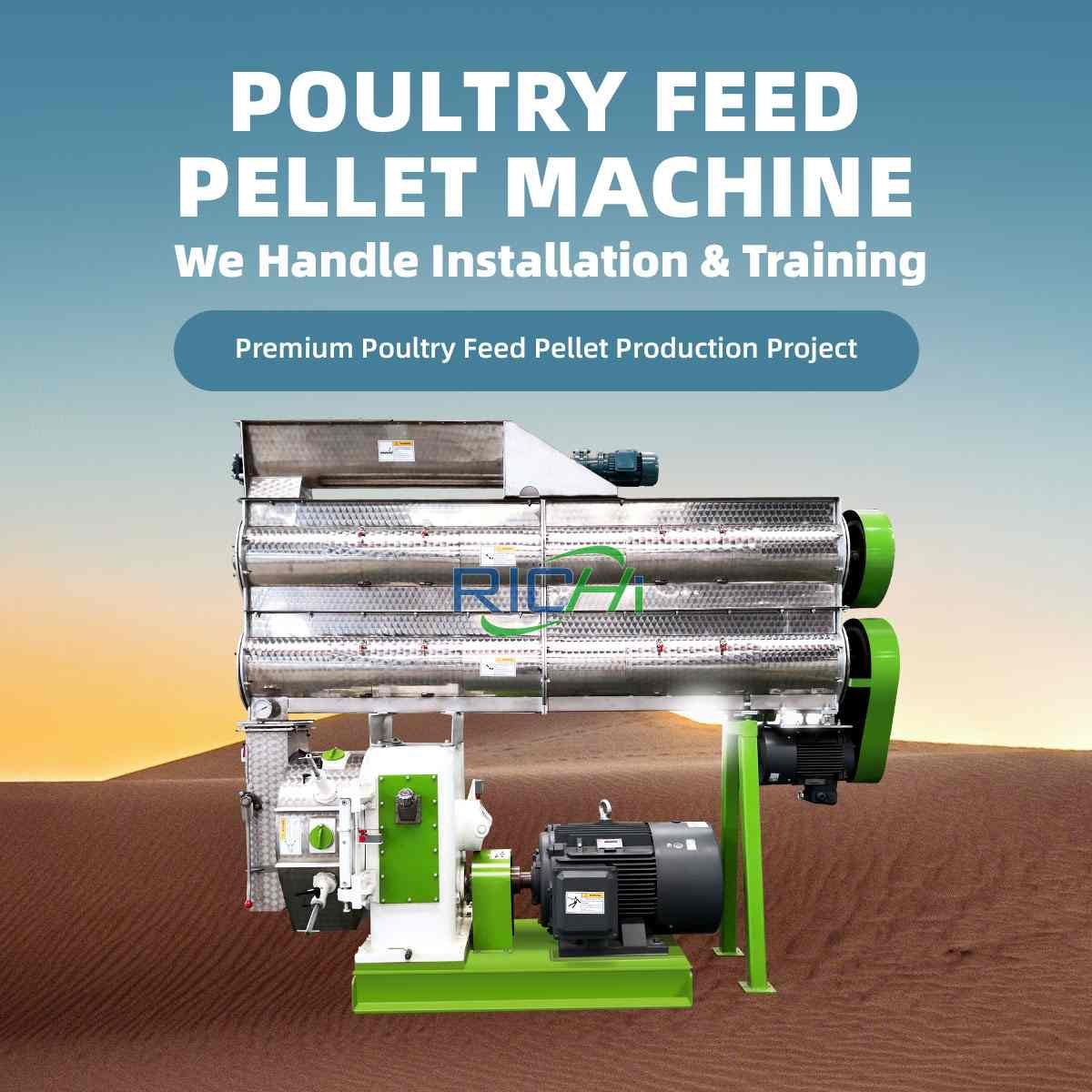

- Feed Pellet Mill: The core equipment of the production line which compresses mixed powdery feed into granular products. Different types of pellet mills are designed for specific animal feed production as detailed below.

- Cooling and Screening Equipment: Cools the high-temperature granular feed just produced to room temperature to prevent moisture regain and mildew. The screening equipment removes unqualified particles ensuring the uniformity of finished feed.

- Packaging Equipment: Automatically weighs and packages the finished feed into bags facilitating storage transportation and sales.

Specialized Pellet Mills for Diverse Animal Feed Production

Different animals have distinct feeding habits and nutrient requirements which require specialized pellet mills to produce suitable feed. Here are the common types tailored for specific animal species:

- Poultry Feed Pellet Mill: Designed for producing feed for chickens ducks geese and other poultry. Poultry feed requires small particle size (2-4mm) high hardness and good palatability. The pellet mill adopts a high-speed rotating die and roller structure to ensure uniform particle size and high pelleting rate. It can handle high-protein raw materials such as soybean meal and fish meal effectively retaining nutritional components.

- 1-45t/h Pig Feed Pellet Machine: Suitable for different growth stages of pigs from suckling piglets to fattening pigs. Pig feed has varying particle sizes and hardness requirements—for example suckling piglet feed needs finer particles (1.5-2.5mm) and better digestibility. The pellet mill is equipped with adjustable die holes and pressure rollers to adapt to different feed formulas and particle size requirements.

- Ruminant Feed Pellet Mill: Used for producing feed for cattle sheep goats and other ruminants. Ruminant feed often contains a large amount of roughage such as straw and hay. The pellet mill has strong extrusion capacity and a special die design that can compress roughage into high-density pellets improving feed intake and digestibility. It can also add molasses and other additives to enhance palatability.

- Aquatic Feed Pellet Mill: Specialized in producing floating sinking or slow-sinking feed for fish shrimp crabs and other aquatic products. Aquatic feed requires strict water stability to prevent nutrient loss in water. The pellet mill adopts a low-temperature pelleting process and special binders to ensure that the feed remains intact in water for a long time. It can also produce floating feed that is convenient for feeding management and reducing water pollution.

For more information on feed pellet mills, please visit:https://www.richimanufacture.com/poultry-feed-pellet-plant/

Advantages of Investing in a Professional Animal Feed Pellet Plant

Investing in a professional animal feed pellet plant brings multiple benefits to feed manufacturers and large-scale breeding enterprises:

- Improved Production Efficiency: Automated production lines greatly reduce manual intervention with a production capacity ranging from 1 ton per hour to 50 tons per hour meeting the needs of different scales of production. Continuous operation ensures stable output and shortens production cycles.

- Enhanced Feed Quality: Standardized production processes from raw material processing to finished product packaging ensure consistent feed quality. The pelleting process improves nutrient digestibility reduces feed wastage by 15%-25% and extends feed storage life.

- Cost Savings: Large-scale production reduces raw material procurement costs and labor costs. By utilizing local agricultural by-products such as straw and bran the production line maximizes resource utilization further lowering production costs.

- Flexibility and Customization: A well-designed production line can be adjusted according to different feed formulas and animal types realizing multi-purpose production. It can easily switch between producing poultry swine ruminant and aquatic feed meeting market diversification needs.

RICHI Animal Feed Pellet Plant Trusted by Global Users

When selecting an animal feed pellet plant choosing a reputable brand is essential. RICHI a professional manufacturer of feed machinery with decades of experience has won wide recognition from global users for its reliable products and comprehensive services. RICHI’s animal feed pellet plant integrates advanced technology and practical experience covering all types of specialized pellet machines for different animals.

RICHI’s production lines feature modular design allowing users to customize configurations according to their production scale and feed types. Key components such as die and roller are made of high-quality alloy materials undergoing special heat treatment ensuring long service life and stable performance. In addition RICHI provides one-stop services including pre-sales consulting production line design installation and commissioning and after-sales maintenance ensuring that users can use the equipment with confidence.(try this web-site)

Key Considerations for Choosing an Animal Feed Pellet Plant

To select the most suitable animal feed pellet plant consider the following factors:

- Production Scale and Demand: Determine the production capacity of the line based on your daily or annual feed demand. Small-scale farms can choose a compact production line with a capacity of 1-5 tons per hour while large feed factories need large-scale lines with a capacity of 10 tons per hour or more.

- Target Animal Species: Select the corresponding specialized pellet mill and production process according to the main animal species you serve. For example if focusing on aquatic feed prioritize a production line with low-temperature pelleting and water stability enhancement functions.

- Equipment Quality and Durability: Inspect the quality of key components such as die roller and motor. Choose equipment with high wear resistance corrosion resistance and stable performance to reduce later maintenance costs.

- Automation Level: Evaluate the automation level of the production line according to your labor resources and management level. Fully automated lines can reduce manual operation but have higher investment while semi-automated lines are more suitable for small-scale operations with limited budgets.

- After-Sales Service: Ensure the manufacturer provides comprehensive after-sales service including technical support spare parts supply and maintenance services. Timely after-sales service can minimize production downtime caused by equipment failures.

Conclusion Invest in the Right Animal Feed Pellet Plant for Sustainable Development

An efficient and professional animal feed pellet plant is a key investment for feed manufacturers and large-scale breeding enterprises to achieve sustainable development. It not only improves production efficiency and feed quality but also enhances market competitiveness.

By considering factors such as production scale target animal species equipment quality and after-sales service and choosing a trusted brand like RICHI you can select the most suitable animal feed pellet plant. Whether producing poultry swine ruminant or aquatic feed a well-designed production line will help you seize market opportunities and achieve long-term profitability.