1. Introduction: The Importance of Chicken Feed in Poultry Farming

Poultry farming has become one of the fastest-growing sectors in the global livestock industry, providing affordable protein and employment opportunities worldwide. Central to modern poultry production is high-quality feed, which directly impacts growth rates, egg production, and overall flock health. A chicken feed making machine plays a crucial role in producing consistent, nutrient-rich pellets tailored to the dietary requirements of broilers, layers, and breeder chickens.

Traditional feeding methods, often based on raw grains or leftover kitchen scraps, provide inconsistent nutrition and increase feed wastage. Mechanized feed pellet production ensures that chickens receive balanced nutrients efficiently, improving feed conversion ratios, reducing costs, and supporting sustainable farm operations.

2. Historical and Cultural Context of Poultry Feeding

Chickens have been domesticated for thousands of years, with origins traced back to Southeast Asia. Historically, small-scale poultry farmers relied on natural foraging, grains, and household scraps to feed their flocks. While sufficient for subsistence farming, these practices often resulted in uneven growth and variable egg or meat production.

The invention of the chicken feed pellet making machine reflects the modernization of poultry husbandry. Pelletized feed allows farmers to deliver precise nutrition to their flocks, reduces selective feeding, and minimizes waste. Countries with long-standing poultry cultures, such as the United States, China, and Brazil, have widely adopted mechanized feed production, combining traditional poultry practices with technological innovations to improve efficiency and productivity.

3. Components and Function of a Chicken Feed Pellet Making Machine

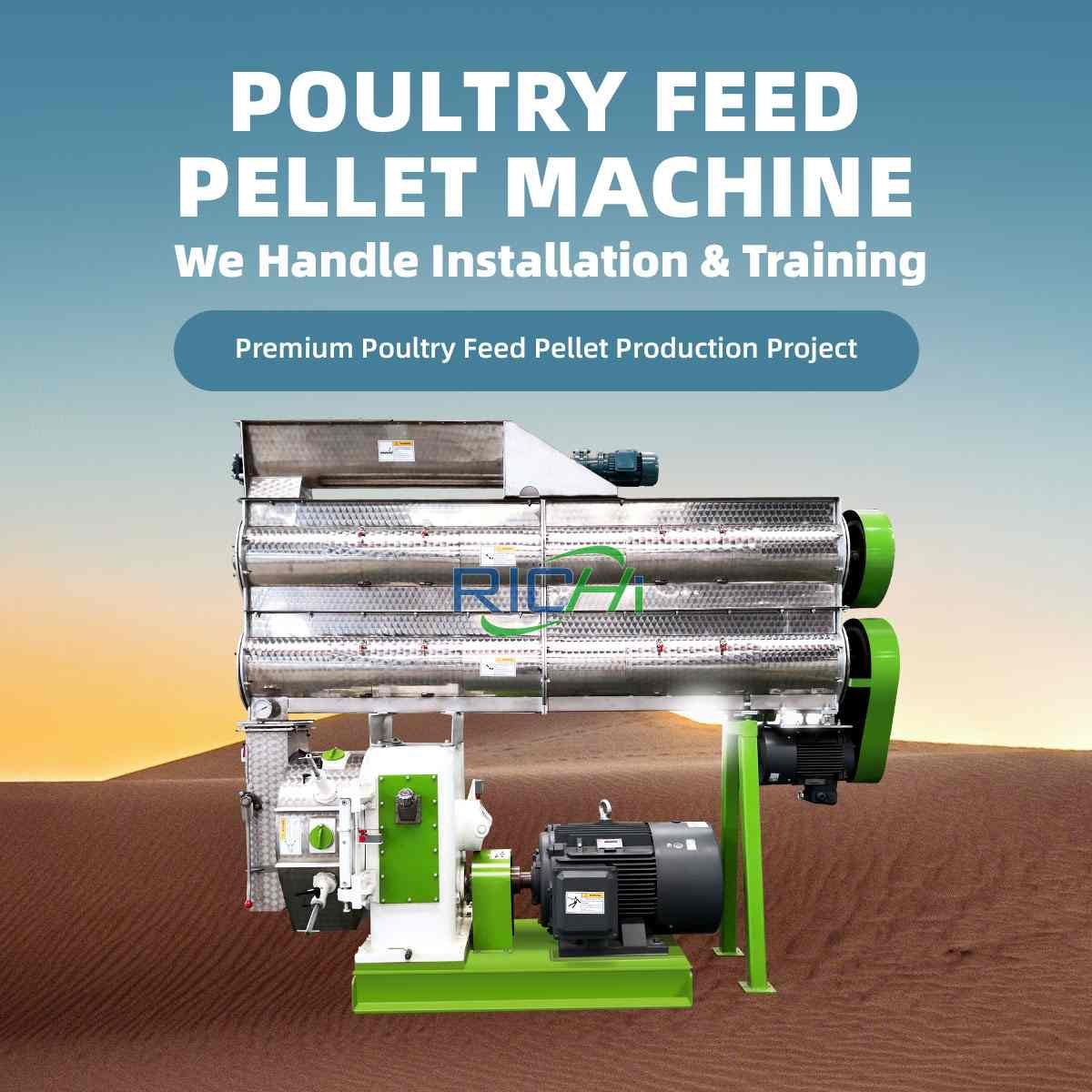

A typical chicken feed pellet making machine system includes several essential components designed for high-quality feed production:

Raw Material Grinder / Hammer Mill: Reduces corn, soybean meal, wheat, and other ingredients into fine powder for uniform mixing.

Mixer: Ensures even distribution of proteins, vitamins, minerals, and feed additives.

Pellet Mill / Extruder: Compresses feed into uniform pellets suitable for chickens at different growth stages.

Dryer: Reduces moisture content to prevent spoilage and prolong shelf life.

Cooling System: Stabilizes pellets, preventing breakage during storage and transport.

Packaging Unit: Prepares feed for storage, transport, and commercial sale.

Modern machines often include automated controls, adjustable pellet sizes, and energy-efficient designs. Reputable suppliers like RICHI provide modular systems suitable for small poultry farms and industrial-scale operations. https://richipelletizer.com/chicken-feed-pellet-maker/

4. Advantages of Using a Chicken Feed Pellet Making Machine

Investing in a chicken feed pellet making machine offers multiple benefits for poultry farms:

Balanced Nutrition: Ensures uniform delivery of proteins, fats, vitamins, and minerals to promote growth and egg production.

Efficient Feeding: Reduces feed waste and optimizes feed conversion ratios.

Consistency: Automated systems produce uniform pellet size and nutrient content.

Scalability: Machines can be adapted for small farms or large commercial operations.

These benefits enhance overall flock health, improve productivity, and support cost-effective and sustainable poultry farming.

5. Technological and Environmental Considerations

Producing high-quality chicken feed pellets requires precise control over moisture content, temperature, and pellet density. Improper processing can result in crumbling, nutrient loss, or poor digestibility.

Modern chicken feed pellet making machines, including models from RICHI, integrate advanced extrusion and drying technologies with automated monitoring systems. These innovations ensure consistent feed quality, optimize energy efficiency, and maintain pellet durability.

Environmentally, mechanized pellet production reduces feed wastage, lowers energy consumption, and allows the use of agricultural by-products, contributing to sustainable and eco-friendly poultry farming practices. Special info

6. Economic and Market Significance

Feed costs account for a significant portion of poultry production expenses, often up to 60–70% of total operational costs. Using a chicken feed pellet making machine allows farms to produce feed on-site, reducing dependence on external suppliers and minimizing costs.

The global poultry feed market continues to grow due to increasing demand for chicken meat and eggs. Mechanized feed production enables farms to meet both domestic and export standards while improving operational efficiency. High-quality pellets improve flock growth, reduce disease incidence, and support profitable poultry farming operations.

7. Choosing the Right Chicken Feed Pellet Making Machine

Selecting an appropriate chicken feed pellet making machine involves considering several factors:

Capacity: Ranges from small-scale 0.5–2 tons per hour systems to industrial 5–20 tons per hour lines.

Feed Type: Pellets or crumbles tailored to broilers, layers, or breeders.

Automation Level: Advanced control systems reduce labor and ensure consistent pellet quality.

Supplier Reliability: Trusted manufacturers such as RICHI Manufacture provide technical support, spare parts, and long-term maintenance.

Proper machine selection ensures consistent feed quality, operational efficiency, and sustainable production.

8. Cultural and Nutritional Importance

Chicken meat and eggs are vital sources of protein, essential amino acids, and micronutrients in human diets worldwide. A chicken feed pellet making machine ensures that poultry receives balanced nutrition for optimal growth, egg production, and overall health.

Culturally, poultry farming plays a central role in rural livelihoods, providing income and employment opportunities. Mechanized feed production supports these communities by improving productivity, reducing labor, and allowing farmers to adopt modern technology without compromising traditional farming practices.

9. Conclusion: Investing in Sustainable Poultry Farming

A chicken feed pellet making machine represents a strategic investment in efficient, sustainable, and profitable poultry farming. By producing nutrient-rich, uniform pellets, farmers can improve flock health, reduce feed waste, and enhance productivity.With reliable solutions from suppliers such as RICHI, farms can scale production, maintain feed quality, and meet rising global demand for poultry products. Modern pelletized feed production combines economic efficiency, environmental responsibility, and technological innovation, shaping the future of sustainable poultry farming. Poultry Feed Production Line In Afghanistan